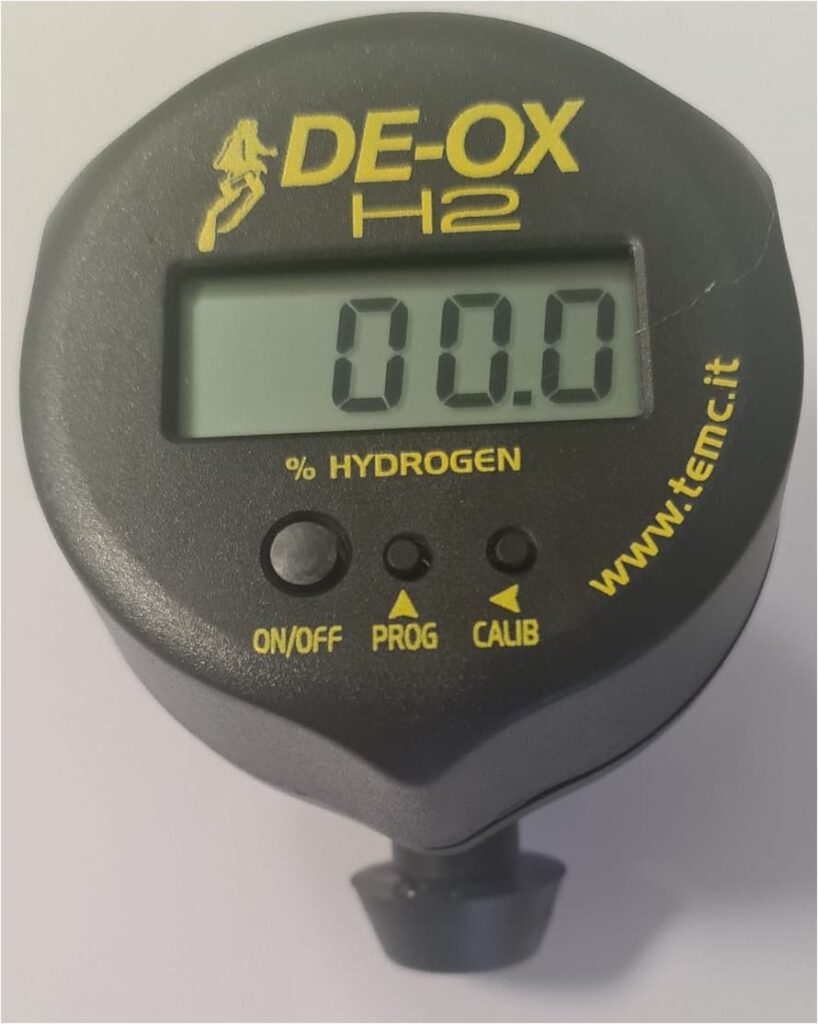

DE-OX H2 HYDROGEN analyzer

DE-OX® H2 represents the simplest and up-to-date mobile measurement instrument for the analysis of hydrogen in mixed gas. Unique features include two level alarms, standard analog 4-20 mA and Open Collector outputs.

It is possible to choose thermal conductivity or electrochemical technologies for the sensing probe of the unit.

DE-OX® H2 comprises in just one integrate device the hydrogen sensor, the electronic board and the battery.

DE-OX® H2 can be used for continuously reading during mixed gas filling. It can alert and help in switching off the compressor if the hydrogen value goes over the set alarms range.

DE-OX® H2 can be also used for safety reason in the gas content into any environment (in diffusion mode). It alerts the operators in case of dangerous concentration. It is important to point the sensor in a proper position as Hydrogen gas tends to ascend, and it is possible the sensor will not detect any Hydrogen concentration, even if it is present.

The unit is based on an innovative sensor developed by TEMC® for respiratory use and for monitoring the respiratory parameters in saturation dives.

It is strongly suggested to chek the analyser prior any use (bump test with sample gas).

- Hydrogen indication in any Oxygen-Nitrogen mix in the range 0.0-100.0% of volume or 0-100% LEL (i.e. 4% volume).

- 0,01 % resolution.

- Full digital measurement instrument.

- Thermal conductivity stainless steel hydrogen sensor developed for marine professional ambient.

- Sensor life up to 10 years

- Auto OFF with switching delay setting.

- No calibration needed.

- Sensor and analyzer autosetting.

- Two custom audible and visible alarms.

- Analog 4-20 mA output for external devices (optional).

- Open Collector output (optional).

- Battery low indicator.

- milliVolt sensor output reading.

- Standard 9 Volt transistor battery.

- External power supply from 8 to 18 VDC VDC (optional). Power consumption 100 mA ca.

- Simple battery and sensor replacement.

- Direct connection to every kind of tank valve with TEMC® rubber cup.

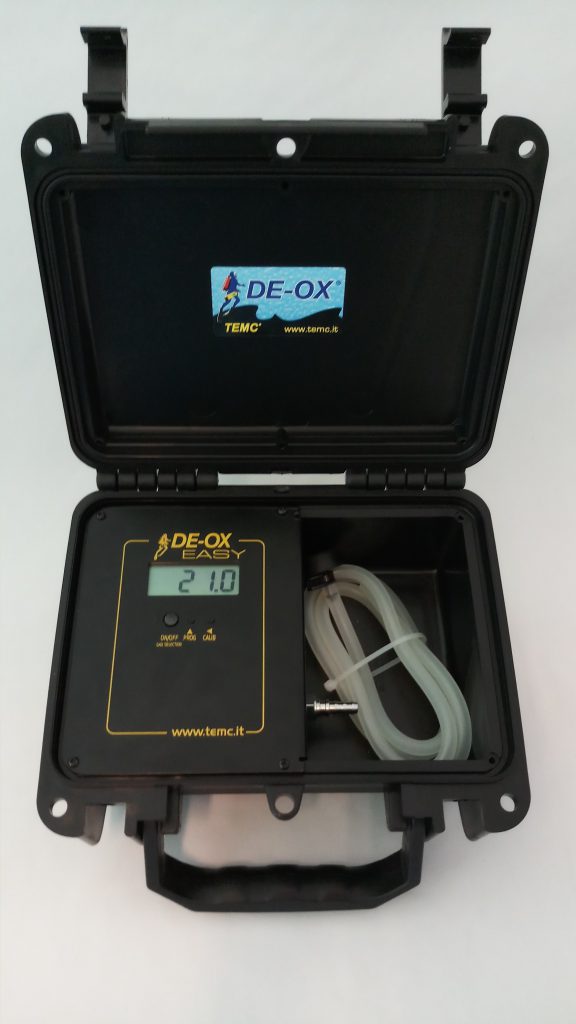

- Soft protection and transport bag.

- Numeric display of 50x35mm.

- Dimensions: max 7,5×4,2 cm weight 350 grams ca.

Thermal Conductivity Hydrogen Sensor Specifications

Stainless steel extra long life sensor based on thermal conductivity technology, with good signal stability with temperature changes. This hydrogen sensor is strictly embedded to its DE-OX® electronic and can not be used without it.

The Hydrogen sensor operates by comparing the thermal conductivity of the measuring gas with air as reference gas. The sensor is calibrated to analyze hydrogen into nitrogen and oxygen gas mix.

All characteristics are based on conditions at 25°C, 50% RH and 1013 hPa

Specifications:

- Measurements range 0÷100% of Hydrogen in air or Nitrogen or oxygen.

- Resolution 0,1%

- Operating humidity from 0 to 95% non condensing. Prevent condensation on the surface of the sensing surface.

- Operating temperature range from 5°C (41F) to 40°C (104F).

- Storage temperature range from -15°C (5F) to 50°C (122F).

- Do not expose sensor to a biased voltage or to a short circuit.

- Response Time <10 sec for 90% response at 23°C.

- Tolerance: ± 0.15 mm

- Accuracy ±2% over full scale.

- Linearity within ±2% over full scale.

- PTFE protection membrane

- Due to the thermal conductivity technology, the accuracy of the sensor is no more warranted if into the gas mix there are gases like: acetylene, ammonia, argon, carbon dioxide, ethane, ethylene, freon, helium, methane, neon, propane, etc.

- When a gas mix with high content of oxygen is analysed, the hydrogen sensor may detect some point of hydrogen into the mix, even if none. This is due to the oxygen thermal conductivity that is slightly different from air.

- Available with optional EX sensor

ATEX certified (flameproof)

II 2G Ex db IIC Gb

I M2 Ex db I Mb

IECEx certified (flameproof)

Ex db IIC Gb

Ex d I Mb

CSA certified (Intrinsically Safe)

CSA Std C22.2 No. 30

UL recognised (Intrinsically Safe)

UL 913

- Do not try to disassemble the sensor. Sealed unit contains delicate electronic device that may be destroyed. If disassembled or handled the sensor could not properly work. Do not wet in any case.

Electrochemical Hydrogen Sensor Specifications

- Output signal 0.5±0.25nA / ppm

- Measuring Range 0–50.000 ppm (0-5% Volume)

- Typical Baseline Range (pure air) ±100ppm

- Resolution at 20°C 0.01%

- Linearity ± 3% full scale

- Repeatability < ±2%

- Response Time at 20°C t90 < 40 s

- Long Term Sensitivity Drift < 2% per month

Operation Conditions:

- Pressure Range 800 to 1200 mbar Operating

- Temperature Range -30°C to +50°C

- Humidity Range 15–90% r.H., non–condensing

- Sensor Life Expectancy > 24 months

CROSS SENSITIVITIES AT 20°C

| Gas | Concentration Used | Reading (ppm H2S) |

| Hydrogen Sulphide | 25 ppm | <2 |

| Sulfur Dioxide | 20 ppm | 0 |

| Carbon Monoxide | 1000 ppm | <300 |

| Nitric Oxide | 50 ppm | <30 |

| Nitrogen Dioxide | 20 ppm | 0 |

| Chlorine | 50 ppm | 0 |

Do not try to disassemble the sensor. Sealed unit contains delicate electronic device that may be destroyed. If disassembled or handled the sensor could not properly work. Do not wet in any case.

In the interest of product improvement, TEMC® reserves the right to alter design features and specifications without notice. Check TEMC® for the latest sensor specifications.

Unless otherwise stated, all product specifications are quoted at standard temperature and pressure.

*Note: The figures in this table are typical values and should not be used as a basis for cross calibration. Cross sensitivities may not be linear and should not be scaled. For some cross interferents break through will occur if gas is applied for a longer time period.

Electromagnetic compatibility test for CE marking:

- CEI EN 61326-1 Electrical equipment for measurement, control and laboratory use – EMC requirements

- CEI EN 55022 Information technology equipment – Radio disturbance characteristics – Limits and methods of measurement

- CEI EN 61000-4-2Electromagnetic compatibility (EMC) – Part 4-2: Testing and measurement techniques – Electrostatic discharge immunity test

Warranty

TEMC®, whose policy is one of continuous quality improvement, reserves the right to modify the technical characteristics of the instrument and manual without prior notice.

TEMC® warrants that its DE-OX H2 computer will be free from defects on material and workmanship for a period of twelve (12) months from the date of delivery, with the exception of sensor not manufactured in-house and that is warranted for six (6) months.

KeyOS srl

KeyOS srl